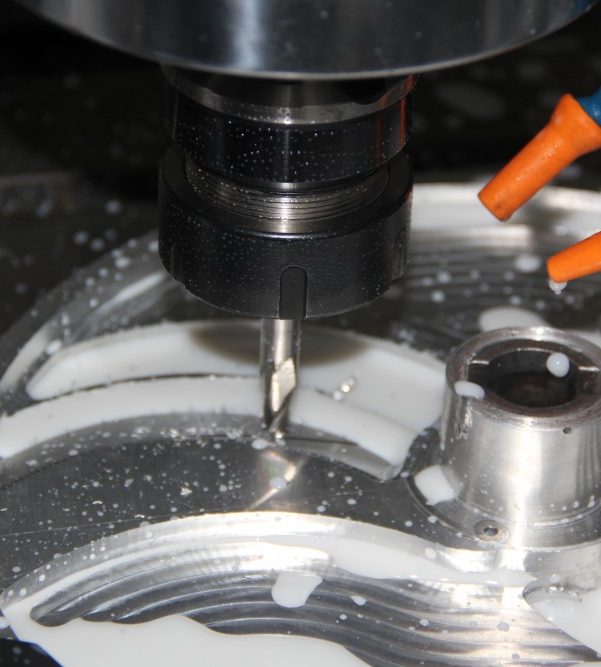

CNC Milling

Our 3 axes CNC machine has a bed size of 1000 x 800 mm, with a retractable additional 4th axis rotary table and it uses the CNC technology and various carbide/ HSS milling and drilling tools to machine regular and irregular shapes on various types of materials including steel, plastic, aluminium and wood.

The machine has the capability to drill/ tap/ bore holes and mill surfaces on custom designed parts using CAD/CAM technology, and we can provide set ups for high volume batch production, and specific parts like moulds, worm gears and high precision parts for other equipment and machines.